InteliSENS SLR mini Series PROTON Vietnam

Hãng sản xuất: Proton

InteliSENS SLR MINI PROTON Vietnam, InteliSENS SLR MINIPROTON , InteliSENS SLR MINIPROTON Viet nam, InteliSENS® SLR MINIPROTON Vietnam

PROTON , PROTON Vietnam , PROTON Viet nam

Features

- Non-contact, high-speed, solid-state laser speed and length measurement with no slippage, drift, mechanical wear or maintenance compared with contact wheel / roller systems.

- Wire optomized SL mini-W series version available for wire and cable applications

- Bidirectional speed and length measurement; accurately measures speed and length during line stoppage, reversal and creepage.

- Ultra-compact design with a footprint comparable to a smartphone.

- Optimized for sheet material and converting applications.

- UKAS-traceable calibration; accuracy better than 0.05% and repeatability better than 0.02%.

- Rugged industrial design for use in factory environments.

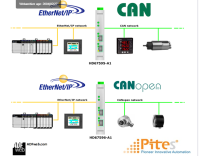

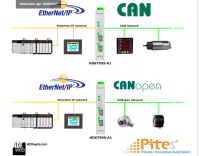

- Available fitted with industry-standard communcations interfaces for easy integration with PLCs and production line equipment.

- Excellent value with low cost of ownership

Introduction

Proton Products InteliSENS® SLR mini Series non-contact, bidirectional speed and length gauges provide extremely accurate speed and length measurements in almost any sheet material or converting application.

Production processes for web products, woven and non-woven materials, paper, plastic film, tapes, building materials, flooring and labelling can all be measured using the laser Doppler method.

Applications requiring a precise cut-to-length process benefit from the non-slip and highly accurate laser measurement technique which reduces scrap, increases uptime and improves material yield by eliminating product “Give Away” or “Short Length” claims.

InteliSENS® SLR mini Series gauges are money-saving, direct replacements for traditional problematic and high-maintenance contact wheel and roller-type devices and are extremely easy to install and operate. Integration with production line controllers such as PLCs is eased by the availability of a wide variety of industry standard communications interfaces.

Operating principle – Laser surface velocimeter

Proton Products InteliSENS® SLR mini Series speed and length gauges illuminate the measured surface with an interference pattern created by the intersection of two laser beams. The alternating bright and dark interference fringes modulate the light scattered by the object with a frequency proportional to the object speed. This scattered light is detected by a photodiode and the electrical signal digitally processed to determine the frequency and hence the speed. Object length is then calculated by integrating the speed measurement over time.

The InteliSENS® SLR mini Series bidirectional speed and length gauges extend this principle by using a high-frequency Bragg cell modulator to illuminate the measured surface with a scanning interference pattern, which generates an oscillating light signal even when the object is stationary. Direction of motion is determined by whether the scattered light frequency is higher or lower than the stationary frequency.

|

Specification

|

Minimum

|

Typical

|

Maximum

|

Units

|

|---|---|---|---|---|

| Accuracy* | 0.05 | % | ||

| Repeatability | 0.02 | % | ||

| Acceleration | 500 | m/s2 | ||

| Internal measurement rate | 200 | kHz | ||

| Measurement output interval | 20 | µs | ||

| Laser spot diameter | 3 | mm | ||

| Operating temperature | 5 | 40 | °C | |

| 41 | 104 | °F | ||

| Ingress protection | IP67 | |||

| Weight | 1.1 | kg | ||

| 2.4 | lb | |||

| Length | 142 | mm | ||

| 5.59 | inch | |||

| Width | 104 | mm | ||

| 4.09 | inch | |||

| Height | 52 | mm | ||

| 2.05 | inch | |||

| Power supply | 15 | 24 | 25 | VDC |

| Power consumption | 8 | W |

*only valid if the measured object is positioned within the central 20% of the depth-of-field.

| Measurement units (end-user configurable) |

Speed | metres/minute | feet/minute | |

| Length | metres | feet | yards | |

| Laser safety control inputs | Laser | External closed contact to ground enables laser diode. | ||

| Shutter | External closed contact to ground opens laser shutter. | |||

| Shutter status output | Electrical | N-channel MOSFET pull-down (for connection to user-supplied opto-isolated relay). | ||

| Maximum voltage: 30VDC | Maximum current: 100mA | |||

| Function | Pulled to ground when laser shutter is open. | |||

| 3×Logic inputs (end-user configurable) |

Electrical | Maximum input voltage: 24VDC | ||

| Function | Length reset | Display hold | Length hold | |

| Speed hold | Direction | Pause | ||

| 2×Logic outputs (end-user configurable) |

Electrical | N-channel MOSFET pull-down (for connection to user-supplied opto-isolated relay). | ||

| Maximum voltage: 30VDC | Maximum current: 100mA | |||

| Function | Gauge OK | Laser at temp | Laser on | |

| Measuring | Preset Length 1 | Preset Length 2 | ||

| 2×Differential pair pulse outputs (end-user configurable) |

Electrical | Opto-isolated differential pair | ||

| Output voltage: 5V or user supplied (up to 24V) | ||||

| Maximum frequency: 1MHz | ||||

| Function | Independent | Quadrature pair | ||

| CANbus communications | Connects to an optional Proton Products CDi interface display unit | |||

| Serial communications | RS-232 | |||

| Ethernet communications | Modbus protocol | |||

| Optional communications (factory-installed, choice of one, replaces standard Ethernet interface) | PROFIBUS | Ethernet/IP | DeviceNET | |

|

Model

|

SLR mini 1220

|

SLR mini 3060

|

Units

|

|---|---|---|---|

| Part number | 00050MC011 | 00050MC012 | - |

| Stand-off distance | 120 | 300 | mm |

| 4.72 | 11.8 | inch | |

| Depth-of-field | 20 | 60 | mm |

| 0.79 | 2.36 | inch | |

| Maximum speed (bidirectional) | 2000 | 5000 | m/min |

| 6560 | 16400 | ft/min |

Mr. Tuan

Mr. Tuan hongthanh86

hongthanh86