InteliSENS DG Series Diameter Gauge PROTON Vietnam

Hãng sản xuất: Proton

InteliSENS DG Series Diameter Gauge PROTON Vietnam, InteliSENS DG Series Diameter GaugePROTON , InteliSENS DG Series Diameter Gauge PROTON Viet nam, InteliSENS DG Series Diameter Gauge Proton Vietnam

PROTON , PROTON Vietnam , PROTON Viet nam

Features

- Non-contact, scanning laser beam diameter measurement.

- 1 or 2 axis models available in 30, 60 or 130mm maximum diameters.

- 600 scans per second per axis.

- Measures wire, cable and cylindrical object diameters (both opaque and transparent such as glass rod) and envelope diameter for braided or helically-stranded cables.

- Single Scan Flaw Detection (SSFD) for detection of insulation lump and neck flaws.

- Compact and robust industrial design for use in harsh factory environments (IP65 / NEMA4 protection).

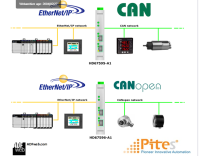

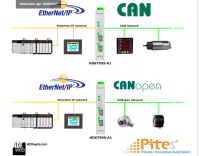

- Integrates seamlessly via CANbus with Proton Products NEXiSTM CS Series Controllers for diameter driven control of the insulation extrusion process.

Proton Products InteliSENS® DG Series laser scanning diameter gauges provide accurate and repeatable measurements for products manufactured within critical tolerance limits.

Robust industrial design and use of advanced digital signal processing electronics make InteliSENS® DG Series gauges extremely reliable and easy to integrate into production control systems.

Each InteliSENS® DG gauge head features RS232 and CANbus as standard; PROFIBUS, Ethernet/IP or DeviceNET industrial communications interfaces may also be provided as an option integrated within the DG gauge.

Analogue or relay contact outputs may also be provided as an option integrated within the DG gauge or as standard on NEXiS® CS Series Controllers connected to the DG gauge (please click here to see the NEXiS® CS Series of Controllers). The NEXiS® CS series Controllers provide cost effective and accurate diameter control for manufacturers of wire, cable, tubing, piping and many other continuously extruded materials.

Operating Principle

Proton Products InteliSENS® DG series diameter gauges rapidly scan a laser beam across the object under measurement. The laser beam is focused by a receiving lens onto a photodiode and the electrical signal digitally processed by a Proton-designed FPGA processor. The time duration for which the object obscures the laser beam is directly proportional to the object diameter.

|

Specification

|

Minimum

|

Typical

|

Maximum

|

Units

|

|---|---|---|---|---|

| Measurement rate per axis | 600 | scan/s | ||

| Operating temperature | 5 | 45 | °C | |

| 41 | 113 | °F | ||

| Relative humidity (at 38°C / 105°F) | 90 | % | ||

| Environmental protection | IP65 | - | ||

| NEMA4 | - | |||

| Power supply | 15 | 24 | 25 | VDC |

| Power consumption | 24 | W |

| Measurement units (end-user configurable) | mm | inch | |

| Standard communications | CANbus | RS-232 | |

| Optional in-gauge interfaces (factory-installed, choice of one) | PROFIBUS | Ethernet/IP | DeviceNET |

| Analogue outputs | Relay contact outputs | ||

|

Model

|

DG2006

|

DG1030

|

DG2030

|

DG1060

|

DG2060

|

DG1130

|

DG2130

|

Units

|

|---|---|---|---|---|---|---|---|---|

| Axes | 2 | 1 | 2 | 1 | 2 | 1 | 2 | - |

| Gate size | 30 | 60 | 130 | mm | ||||

| 1.18 | 2.36 | 5.12 | inch | |||||

| Minimum diameter | 0.1 | 0.2 | 0.5 | mm | ||||

| 0.004 | 0.004 | 0.02 | inch | |||||

| Maximum diameter | 6.5 | 27 | 57 | 130 | mm | |||

| 0.256 | 1.06 | 2.24 | 5.12 | inch | ||||

| Resolution | 0.1 | 1 | 1 | 1 | µm | |||

| Accuracy | ±(1µm + 0.008% of object diameter) | ±(1.5µm + 0.008% of object diameter) | ±(10µm + 0.008% of object diameter) | - | ||||

| Weight | 7.5 | 5 | 7.5 | 8 | 14 | 10 | 20 | kg |

| 16.5 | 11 | 16.5 | 17.6 | 31 | 22 | 44 | lb | |

| Length | 260 | 290 | 260 | 425 | 360 | 504 | 674 | mm |

| 10.24 | 11.43 | 10.24 | 16.75 | 14.17 | 19.68 | 26.54 | inch | |

| Width | 66 | 66 | 66 | 68 | 68 | 68 | 68 | mm |

| 2.6 | 2.6 | 2.6 | 2.68 | 2.68 | 2.68 | 2.68 | inch | |

| Height | 270 | 170 | 270 | 212 | 402 | 230 | 654 | mm |

| 10.63 | 6.7 | 10.63 | 8.35 | 15.83 | 9.06 | 25.75 | inch | |

Mr. Tuan

Mr. Tuan hongthanh86

hongthanh86